The Environmental portion, the “E” of ESG considers how companies use natural resources and the effect of its operations on the environment, both in its direct operations and across its supply chains. These criteria may include a company’s energy use, waste, pollution, natural resource conservation, among others.

AHM member companies have been pioneers in adopting strategies to reduce negative environmental impacts. Depending on their location and activity, these include, but are not limited to: efficient use of energy, diversification of the energy resources to use more renewables, water conservation, waste reduction/reuse/recycling and reforestation.

Our first sampler – showcases projects of improved energy efficiency and diversification and transition to renewable energy sources from AHM-member companies: Coats, Elcatex, Fruit of the Loom, Hanes, Pinehurst and Zip San José.

Note: Companies integrate various components and projects in each of the ESG pillars into their strategies and according to their material issues. We cannot share all of the projects at once, so our rotating gallery will be regularly updated.

Renewable energy

ESG and sustainability are linked through renewable energy, for example, as integrating renewables into your energy strategy overlaps with social values and outcomes, all of which are driven and supported by corporate governance.

https://www.usourceenergy.com/blog/5-ways-sustainability-and-esg-create-business-value/

Following are some of the renewable energy initiatives AHM companies are implementing:

ELCATEX Group

https://www.elcatex.com/sustainability/

The Honduran Grupo Elcatex was founded in 1960 and has evolved and grown into one of the lead vertically integrated manufacturing operations in the region – from design and innovation, knitting, dyeing, and finishing, cutting & sewing to distribution.

The group has diversified its operations, and its business is sorted into four divisions: textiles and synthetic filament and manufacture; energy; industrial parks; and technology and innovation.

It’s sustainability approach is based on four pillars: Health, Environment, Education, and Community impact.

Committed to creating a way of life that encompasses a clean environment, one in which we limit our waste and reuse materials to their greatest potential, this is why we have invested in innovative solutions to reduce our carbon footprint, “all of our energy comes from renewable technologies which include: biomass, biogas and solar”.

85K Tons/year of Carbon Emissions avoided

Explore ELCATEX’s Environmental Impact Calculator https://www.elcatex.com/sustainability/environment/

Aerial view of ELCATEX’s Solar PV roof

Honduran Green Power Corporation, biomass / renewable energy

Fruit of the Loom

www.fotlinc.com/sustainability/

Fruit of the Loom released its first annual global sustainability report in September 2020 and announced Fruitful Futures https://www.fotlinc.com/sustainability/our-plan/ , the company’s new global sustainability plan – aligned with several of the UN Sustainable Development Goals – which is implemented through three pillars: people centric, planet conscious and product authenticity

In the “Planet-Conscious” pillar…

Fruit of the Loom lays out the work for reducing the environmental impact of its operations and products.

It sets more ambitious goals to reduce its footprint across its supply chain from sourcing raw materials to consumer use and disposal of its products. https://www.fotlinc.com/sustainability/

Since 2012 Fruit of the Loom has been measuring its corporate footprint and investing in energy efficiency and renewable energy. Other commitments include saving water and working towards Zero Waste.

Actions and many projects are underway in Fruit of the Loom’s Honduran operations on each of the components of the Planet Conscious pillar.

One example in energy is the increased use of renewable sources which results in avoided emissions as well as in operating cost savings. Complementing the solar energy, Fruit of the Loom also has its own biomass plant which has a 125 Million KWh generation capacity and over 160,000 tons of steam per year.

The avoided CO2 emission 2021 YTD in Fruit of the Loom Honduran operations amount to 18,000 MT

Mounting electricity-generating solar panels on Fruit of the Loom’s Honduran facilities rooftops

Fruit of the Loom’s Biomass Plant in Honduras

125 Million KWh generation capacity and over 160,000 tons of steam per year.

Hanesbrands Inc.

www.HBISustains.com

In September 2020, Hanes announced its new, wide-ranging 2030 global sustainability goals that include a commitment to setting science-based environmental targets, a goal of improving the lives of at least 10 million people, and addressing the use of plastics and sustainable raw materials in products and packaging.

The goals were launched via a new sustainability website, www.HBISustains.com, designed to increase company transparency and reporting on key metrics, including diversity, human rights benchmarks and risk assessments for investors.

HBI earns 12th consecutive U.S. EPA Energy Star Award

WINSTON-SALEM, N.C.(April 13, 2021) – HanesBrands’ commitment to protect the planet we share – despite the global pandemic that impacted 2020 – has earned the company its 12thconsecutive U.S. Environmental Protection Agency Energy Star Sustained Excellence/Partner of the Year award for continued progress in environmental sustainability.

Ahead of Earth Day, HanesBrands… recognized by the EPA for lowering overall energy use, while increasing use of renewable energy and electricity during 2020.

Solar pv roof – Hanes Plant – Honduras

Pinehurst Manufacturing

www.pinehurstmfg.com

Since 1989, Pinehurst Manufacturing has evolved into a new breed of vendor for the apparel industry. Our Honduras facility has 30 sewing lines within almost 250,000 sq. feet of total manufacturing space and is in the process of adding more equipment securing capacity for small and medium runs as well as large all year programs.

Pinehurst Mnfg.’s environmental strategy is built on short-, medium- and long-term objectives to meet economic, social and environmental necessities to develop a true sustainable society. We base our environmental strategy on the United Nations’ Sustainable Development Goals (SDGs), stressing those goals in which Pinehurst MFG can positively impact the most (SDGs 3,4,6,7,9,11,12,13 and 17)

Energy reduction and more efficient use of energy remains a core objective for us. During the last 3 years, Pinehurst Mnfg.’s optimized our use of natural resources, achieving a 21% reduction in energy consumption.

ZIP San José

www.zipsanjose.com

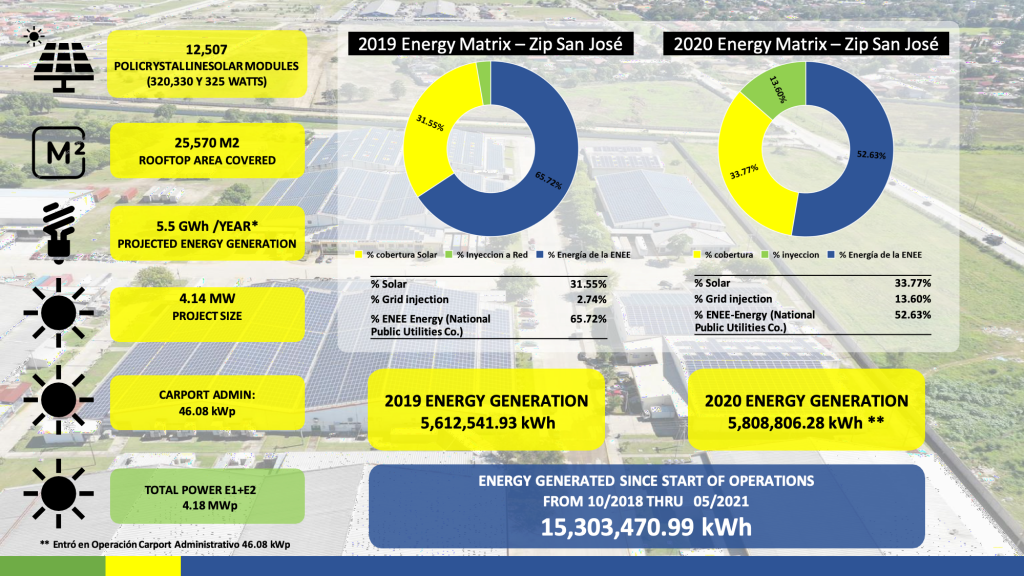

Zip San José is one of the 17 industrial parks in AHM’s membership. Founded in 1993, it has substantial experience in corporate responsibility implementation and has received, every year for the past 12 years, the seal from the local corporate social responsibility foundation FUNDAHRSE. Sustainability is embedded in the services Zip San José provides to its clients, mostly companies in the light manufacturing sector.

On the environmental front, reforestation activities in coordination with local governments and municipalities include the planting of 30,000 plants per year.

ZIP San José has been transitioning to renewable energy, investing mostly on solar pv. Over 35% of the energy consumed in the industrial park is from renewable energy sources. The solar pv option also has collateral benefits such as:

- optimal use of areas within the city (it is the only industrial park in the city of San Pedro Sula)

- It prevents deforestation as it does not require land, since it uses roof solar pv modules

- improving temperature / thermal sensation in the buildings an average of 4°C.

- improvements to the workplace/workspace (i.e. roof over parking areas)

The impact, so far from October 2018 to May 2021, is 5,356.21 tons of CO2 emissions avoided. An estimated equivalent to reforestation would be an area of 608 Ha (1) of forest or 234,464 (2)trees.

- (1) Estimate based> 400 trees/ hectares (5 x 5 meters space distr.)

- (2) Estimate based >1 tree absorbs 22 kgCO2/yr on average

Currently expansion through Phase II of solar pv rooftop project, with an expected impact of further CO2 emissions avoided, to an equivalent of 400 tons / year.

Since implementing the solar PV rooftop system in Zip San José operations, avoided an equivalent to 5,356.21 CO2 emissions. With the expansion (Phase II), ZIP San José will avoid CO2 emissions further to an equivalent of 400 tons / year

Energy efficiency

Energy efficiency benefits are as much about the environment as about reducing cost of production. Today, the textile sector is striving to rely innovation in energy efficiency methods on from initial stages to final stages of fabric production.

AHM member companies throughout the supply chain are implementing these measures. What may seem small in isolation in one operation, taken to scale has great impact.

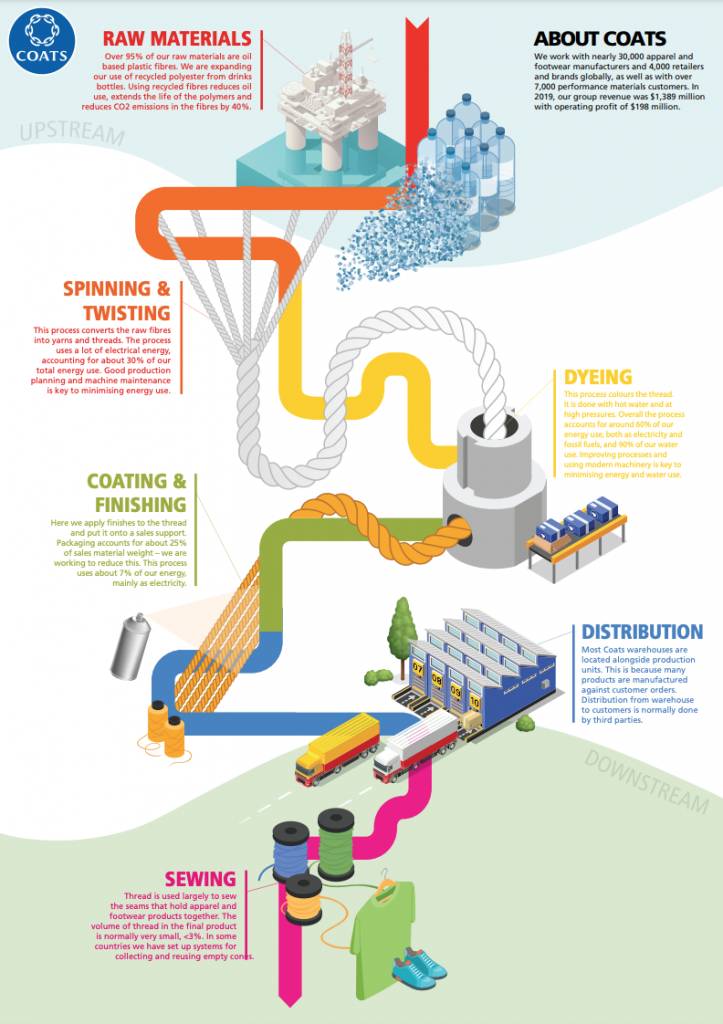

COATS

https://coats.com/en/Sustainability/Sustainability-Overview

Coats has solid sustainability credentials – consistently publishing reports tracking the progress towards the goals established in its sustainability strategy.

With a well-established set of priorities, it has a broad range of practices and projects – varying in nature and size – from innovation and development of sustainable materials such as its EcoVerde 100% recycled line of premium sewing thread to best practices in its operations.

Coats continues to seek opportunities to transition to renewable energy while at the same time addressing the optimization opportunities that exist for reducing its energy use by better planning and higher machine utilization.

Energy consumption reduction by implementing energy efficient lighting.

Coats’ manufacturing process lighting had 54W energy consuming fluorescent lamps.

-

- Fluorescent lamps increase energy consumption, energy cost is high.

- Low illumination.

In 2020, a new lighting system is implemented in which the fluorescent lights are replaced by LED lights with 18W of energy consumption.

-

- Fluorescent lamps were replaced with LED lamps.

- Transition from fluorescent lamps to LED lamps results in more than 50% reduction in lighting energy consumption.

- The number of lamps remains the same.

- Reduced temperature in the working area and better lighting.

The transition from fluorescent lamps to LED lamps results:

-

- Reduction of more than 50% in lighting energy consumption.

- Savings in the project for lamp replacement 31.5k USD /year.

Reforestation

Many AHM member companies have had reforestation initiatives for several years – for broader environmental impact including carbon capture, improving the water supply and biodiversity conservation.

Several of them will be featured in this section.

AHM member company initiatives in upcoming installment.

Waste Management

Waste management refers to the practice of collecting, transporting, processing or disposing of, managing and monitoring various waste materials. It is important to observe sustainability in this aspect so that every bit of waste can be managed in an efficient manner rather than just dumping it all in landfills.

Zero waste in apparel manufacturing is about utilizing existing materials to their full capacity and not producing textile or other material waste. In contrast, while some zero waste products are made from eco-friendly materials, they are more focused on helping the consumer or user of their products refuse single-use products in the future.

Waste minimization prevents the waste from occurring in the first place, rather than treating it once it has been produced by end-of-pipe treatment methods.Here the main focus point is the general waste minimization suggestions for reducing water, chemical and energy consumption; reducing solid waste; and minimizing the emission of toxic substances.

AHM member company initiatives in upcoming installment.

Water

The main environmental impacts from textile industries relate to the wet process stages of textile production. These processes use large volumes of water. Treatment and reuse of this water helps minimize the stress on water resources, in both qualitative and quantitative terms. By introducing improved water reuse systems or other innovations, the textile industry contributes to a more rational water management policy and assist the availability of water sources for potable use.

AHM member company initiatives in upcoming installment.

Prevention extreme weather events

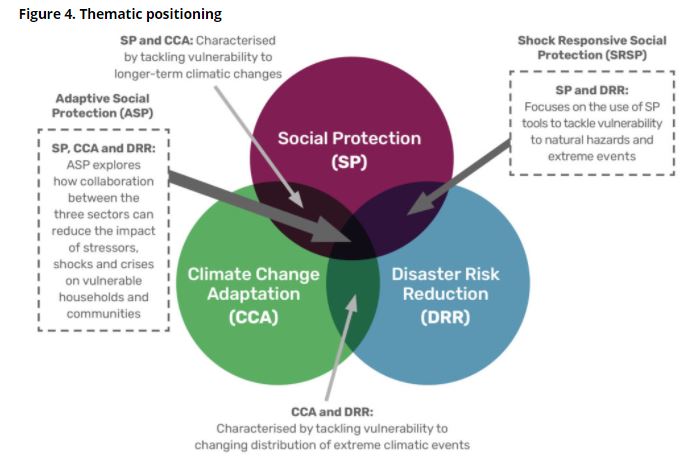

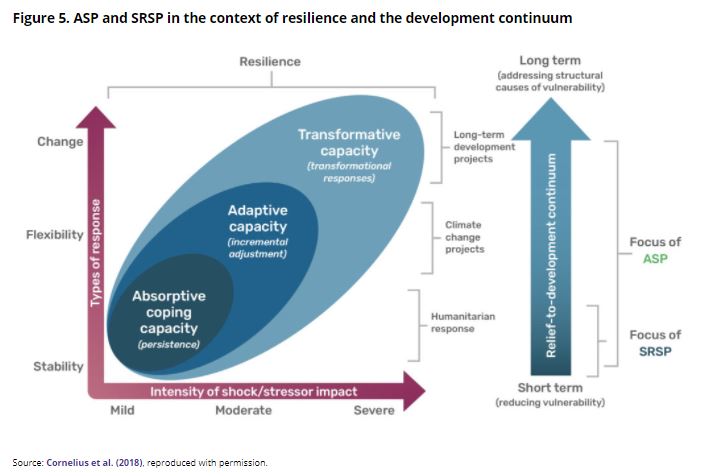

Disaster Risk Reduction (DRR) aims to reduce the damage caused by natural hazards like earthquakes, floods, droughts and cyclones, through an ethic of prevention. Disasters often follow natural hazards. A disaster’s severity depends on how much impact a hazard has on society and the environment. The private sector increasingly engaging in activities to promote Disaster Risk Reduction (DRR) and Sustainable Development Goals .

To achieve resilience to disaster and climate risk these public and private infrastructure investments must be defined by quality as well.

AHM and its member companies have been present during and after extreme weather events, from rescue to relief and support to prevent future negative impact in people, communities and other assets. https://www.ahm-honduras.com/?p=8483

The Honduran Manufacturers Association in conjunction with the Permanent Commission of Contingencies (Comisión Permanente de Contingencia COPECO) and the DIPECHO / TROCAIRE Program of the European Agency for Humanitarian Aid and Civil Protection are working together on a project to link the Private Sector to Disaster Risk Reduction Management.

The intent of this program is for the:

- Creation of Emergency Plans with Social Approach: In addition to the requirements already established for the preparation of Emergency Plans, also include issues such as site emplacement assessments, Qualitative Risk Analysis of buildings and risk analysis focused on the employees.

- Accreditation of the Emergency Committees of the Labor Centers (CODECEL).

- Certification of Industrial Emergency Brigadiers: in the following link you can see the procedure for COPECO to certify the Industrial Emergency Brigadier in his work center

Source: https://www.pgrd-copeco.gob.hn/